TOILET SOAP FINISHING LINE

(CAPACITY:1000kg/H)

OPERATION PLATFORM

操作平台

It is specially designed for amalgamator or mixer.

专用于搅拌机或捏合机。

The structure is made of steel frames with anti-slip plates for the stairs and operation platform.

钢结构,踏步及操作台均采用防滑花纹板制作。

MIXER (CHJ-880)

混合机

One mixing shaft with two mixing paddles is driven by the motor through the gear box and rotating continuously to mix soap noodles, flakes are mixed with all kinds of liquid and solid ingredients inside the mixer chamber. After the mixing, products are discharged through air cylinder controlled discharging door. It can mix products well and even, dyes and ingredients fully blend into the noodles, meeting different customer requirements. All parts contact with soap adopt high quality stainless steel. One the top of it, the whole sealed stainless steel cover is installed to prevent the powder dust from discharging, as well as the safety door switch. The specially designed sigma can mix the soap noodle and any other ingredients intensively. It uses all-hard-teeth precisely-grinded motor-gear reducer. Secondary energy consumption energy-saving motors(national standards).

设备通过电机和减速箱,驱动搅拌轴匀速转动,从而使固定在搅拌轴上的两片搅拌叶在搅拌机筒体内充分混合皂粒、皂片与各种液体和固体添加剂。搅拌结束后,粉料通过下方的气缸控制卸料门自动下料。搅拌效果充分、均匀,色浆、添加剂完全溶入皂基,满足客户不同配方要求。凡与皂料接触部分全部采用优质不锈钢制造。上口安装全封闭不锈钢盖,防止粉尘外泄,并安装安全门开关。独特设计的搅拌浆能使皂粒和添加剂充分混合。采用全磨硬齿轮电机与减速机一体机。此设备已获的CE认证,国际标准二级能耗节能电机。

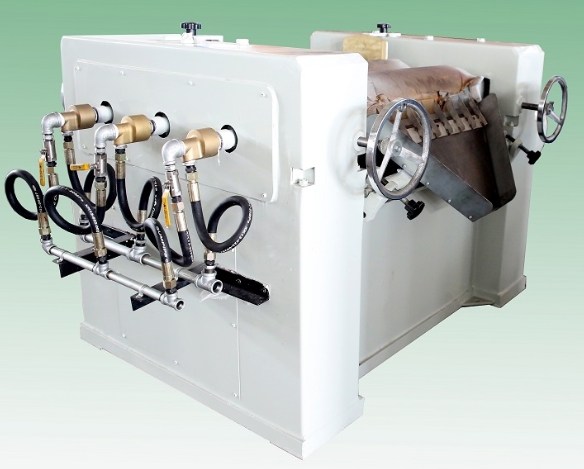

three roll Mill (s-405)

三辊研磨机

Description设备描述:

The Three Roll Mill is used for soap refining. Three rolls are horizontally placed with different rotating speeds. The refining function is achieved by pressing and squeezing force between the adjacent rolls. The main body is made of high quality stain structure, strong and solid. All gears are precisely manufactured and adopt oil bath lubrication to achieve long running life, low noise, less wearing and better reliability. Rolls are made of special alloy for super anti-wearing capability, and fitted with chilling system. Water pipe connector adopts rotating joint. Gap between rolls are adjusted easily to achieve different refining effects and production capacity needs. Secondary energy consumption energy-saving motors(national standards).

三辊研磨机主要用于皂粒研磨。三根辊筒水平方向排列,速度各不相同。皂粒在辊子表面相互挤压和剪切,从而达到研磨作用。机身采用钢结构,坚固结实,全套传动齿轮精密加工,运行过程中采用浸油式润滑,使用寿命长,噪音低,耐磨损,运行稳定可靠。辊筒表面选用冷硬合金材料,辊筒耐磨。水管接头采用旋转接头,可压力回水。辊筒之间的间隙调整方便,从而实现不同的研磨效果和产能需求。国际标准二级能耗节能电机。

DUPLEX VACUUM PLODDER (SYJ-1000)

双联真空出条机

Description设备描述:

This machine has two stages, driven by independent transmission system. The first plodder is acting as a simplex refining to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out in billets through the orifice to feed the downstream cutter or stamper. All gears are precisely manufactured. The screws are made of high quality stainless steel, which have strong corrosion-resistance and are durable for long production. The front end of screw is designed with moving pore plate and fixing pore plate. It can be installed additionally by refining plate or net between them to enforce the martial refined ultimately in 0.01mm inside. The barrel inner body is made of high quality seamless stainless steel, without any leakage. The length and diameter rate of barrel and screw after enhancing length can reach 1:6, it extrude the material effectively and strength the compactedness All other parts which are in contact with the soap are made of high quality stainless steel. Driving part adopts standard hard-teeth fine-ground gear face reducer with wear-resistance, low noise, compact structure which is quite stable and reliable. Specially designed and continuously improved water cooling system is especially suitable for the composite soap, transparent soap, and toilet soap The production capacity can be adjusted by the VFD with the famous brand ABB. The special design for the reducer and the bearing box of the transmission system, avoids the problem that the other similar products’ oil of reducer leakage to the cylinder and avoid to pollute the soap, t The cylinder wall is thick seamless steel tube, to ensure the long-term use and no water leakage, to avoid similar products using other materials barrel is easy to crack .The use of PLC control system, realize the whole line linkage. Secondary energy consumption energy-saving motors(national standards).

双联真空出条机是由两级出料螺杆组成,采用各自独立的闭式减速传动系统。初级出条相当于一个单联精制机,在真空情况下制造皂粒。末级出条,皂粒被压缩,挤压后通过炮口以皂条形式连续输出,供下游切块机和打印机成型。该机减速机采用国内著名品牌全磨齿硬齿面减速机,螺杆采用不锈钢材料,抗腐蚀性强,耐用。初级出条螺杆前端可加装精制板或精制网,对皂料实现0.02mm极限研磨。筒体内筒采用不锈钢无缝管制作,永不渗漏。加长的筒体及螺杆长径比可达1:6,有效地对皂体进行挤压,增强皂料的密实度。其它所有与香皂接触部件均采用优质不锈钢制作。传动部分采用全硬齿面精磨减速机,耐磨损,噪音小,结构紧凑,稳定可靠。特殊设计并持续改进的水冷却系统,特别适合生产复合皂、透明皂和香皂。控制部分可采用变频调速,变频器选用著名品牌ABB,产能可任意调节。独特设计的减速机与轴承箱的传动系统,有效避免了其它同类产品减速机油漏至筒体污染香皂的问题.内筒壁为加厚无逢钢管,确保长期使用不漏水,避免同类产品采用其它材料筒体容易炸裂的缺陷。此设备已获的CE认证国际标准

CUTTING MACHINE (SKJ-III)

电子切条机

采用不锈钢刀片,三菱变频器、伺服电机、伺服控制器、欧姆龙PLC和旋转编码器,德国西格林输送机,7英寸彩色触摸屏。

Apply stainless steel knife blade, MITSUBISHI frequency converter, servo motor, servo controller, OMRON PLC and rotary coder, Germany Siegling conveyer, 7inch color touch screen.

STAMPING MACHINE (XLD-1500)

打印机

输出:3块/次

速度: 5-55次/分钟(推荐速度)

电机功率:2.2kw+0.37kw+0.37kw+0.55kw

压缩空气:6kg

采用自动PLC控制,气动控制元件,电磁阀和模具冷冻系统。

机器采用高质量和高强度碳钢制造

主轴60度旋转

接触物料部分全部用不锈钢或硬质铝合金制造

电器设计和配置:

SEW减速机/电机

采用日本THK直线导轨

日本SMC气动元件

采用西门子PLC、变频器。三菱伺服控制系统。

法国施耐德电子元器件,采用进口品牌传感器

外形尺寸:1590mm(L) x 1920mm(W) x 2100mm(H)

重量:约2.2吨